Diverse Linear Guideway Customization Capabilities

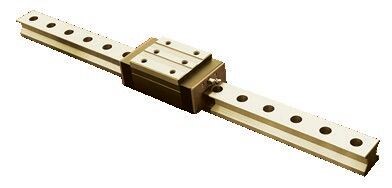

We possess advanced capabilities in the design and manufacturing of a wide variety of linear guideway typesтranging from standard ball-type models to high-precision, complex curved guideways. Our solutions are engineered to meet diverse requirements in load capacity, spatial constraints, and motion configurations.

1. Standard Ball-Type / Roller-Type Guideways Designed for general-purpose linear motion in mechanical systems, available in multiple load and precision grades to support high rigidity and smooth operation. 2. Wide-Rail / Low-Profile Guideways Ideal for systems with limited installation space or low center-of-gravity requirements. Enhances system compactness and running stability. 3. Miniature Guideways (Width 5mmт15mm) Tailored for use in medical devices, precision instruments, and automated optical systems. Available in stainless steel and corrosion-resistant surface treatments. 4. Curved Guideways (Ring, Arc, Ellipse, S-Shape, etc.)

5. Dual-Bearing Rails / V-Type / T-Type / Dual-Guidance Tracks

|

Advanced Surface Treatments & Material Customization

To meet the needs of complex and specialized applications, we offer a wide range of surface finishing and material customization services, including but not limited to:

DLC Hard Coating: Enhances surface hardness and reduces friction for longer service life

Anti-Corrosion Nickel Plating: Suitable for high-humidity or marine environments

Nitriding / Low-Temperature Tempering: Improves fatigue resistance and reduces deformation

Custom Metallurgical Formulations: Designed to withstand extreme temperatures, impact, and vibration conditions

We go beyond the traditional focus on тhardт material properties by also considering machinability, heat treatment stability, and fitment compatibility to optimize the overall system performance.

PreviousяМValue Proposition